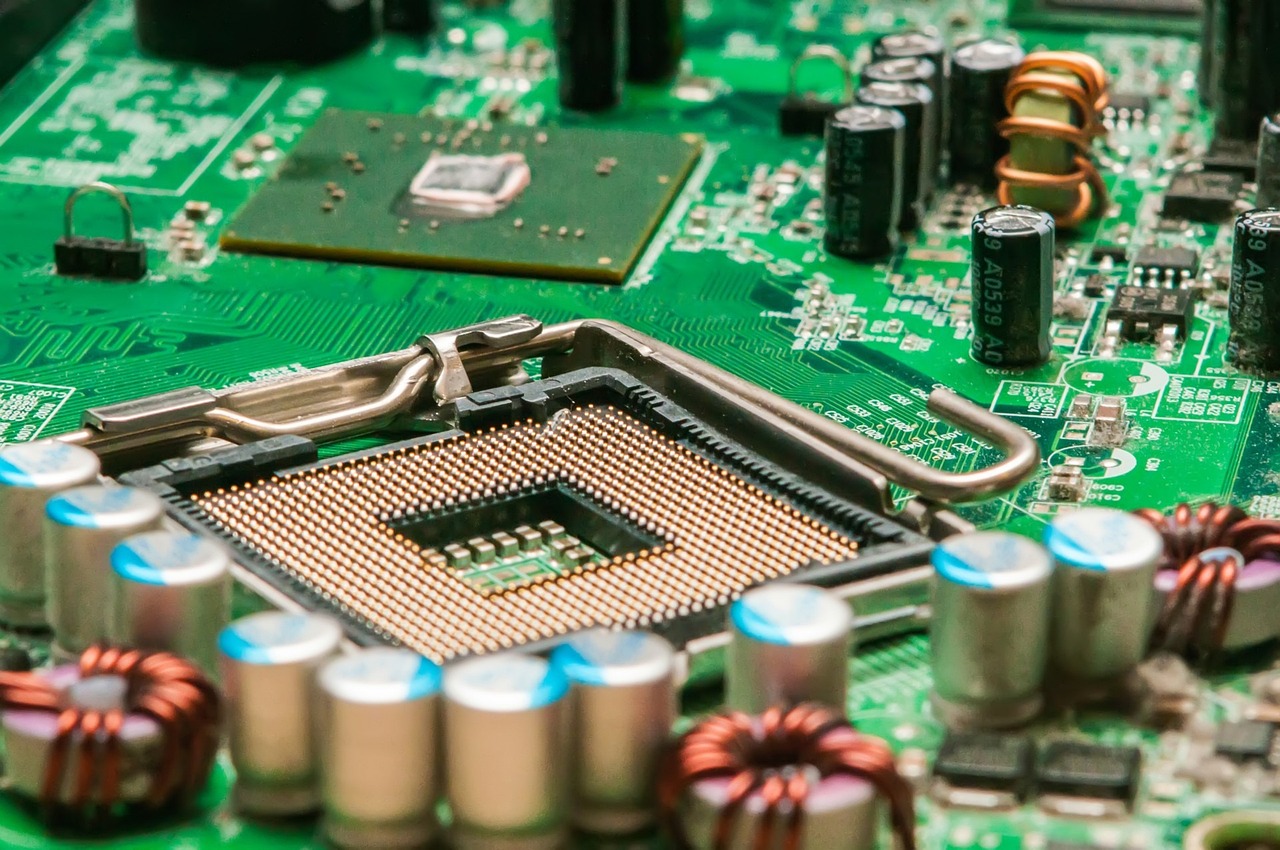

Electrolomas specialises in the manufacture of all types of electronic circuits, among other products and…

Maintenance techniques in the electromechanical sector

The large manufacturers of electrical and electronic equipment, both nationally and internationally, depend to a large extent on applying certain efficient procedures in their maintenance to ensure the correct performance of their equipment and prolong its useful life. In fact, only then will they be able to maintain their competitive edge and meet market demands. Therefore, in this article, the various most relevant electromechanical maintenance methods will be explored in detail.

What electromechanical maintenance techniques exist?

A list of the main maintenance techniques used for this purpose is presented below.

Preventive Maintenance

This proactive technique seeks to avoid possible breakdowns and failures in electromechanical equipment. Through periodic and well-defined inspections, potential problems can be identified and corrected before they become critical situations.

Thus, with its application it helps to reduce unplanned downtime and improves the reliability and efficiency of the devices. It also allows interruptions to be planned in advance, thus avoiding costly production stoppages.

Predictive Maintenance

This method uses advanced technologies, such as sensors and data analysis, to predict the health and performance of equipment. By constantly monitoring key variables such as vibrations, temperatures, and power consumption, manufacturers can anticipate potential failures and make timely and accurate shutdowns.

This optimizes maintenance planning and reduces the costs associated with unexpected repairs. The data collected also allows wear patterns and performance trends to be identified, making it easier to make informed decisions for future improvements.

Corrective maintenance

This reactive technique is applied after a failure or breakdown has occurred in a piece of equipment. Although it is not the preferred option, it is essential to have well-defined plans and procedures in place to act quickly and appropriately in emergency situations.

In this way, this type of maintenance allows restoring the normal operation of the devices and minimizing the negative impacts on production. However, its application should be limited to exceptional cases, since emergency repairs can be costly and affect the overall efficiency of the process.

Proactive maintenance

This type combines elements of preventive and predictive maintenance to anticipate potential problems and maximize equipment performance. Through data analysis and trend studies, manufacturers can implement continuous improvement strategies and process optimization. Thus, this technique boosts operational efficiency and competitiveness in the electromechanical sector, while fostering a culture of continuous improvement in the organization.

In conclusion, as explained, electromechanical maintenance techniques are crucial to ensure the quality and optimum performance of electrical and electronic equipment. At M2B Technologies, they carry out exhaustive control of these methods and, therefore, design and manufacture high-quality electromechanical parts. In their social networks you can keep track of their latest news and products. Likewise, contacting them will make it possible to discover products that help businesses reach the next level of quality in their sector.