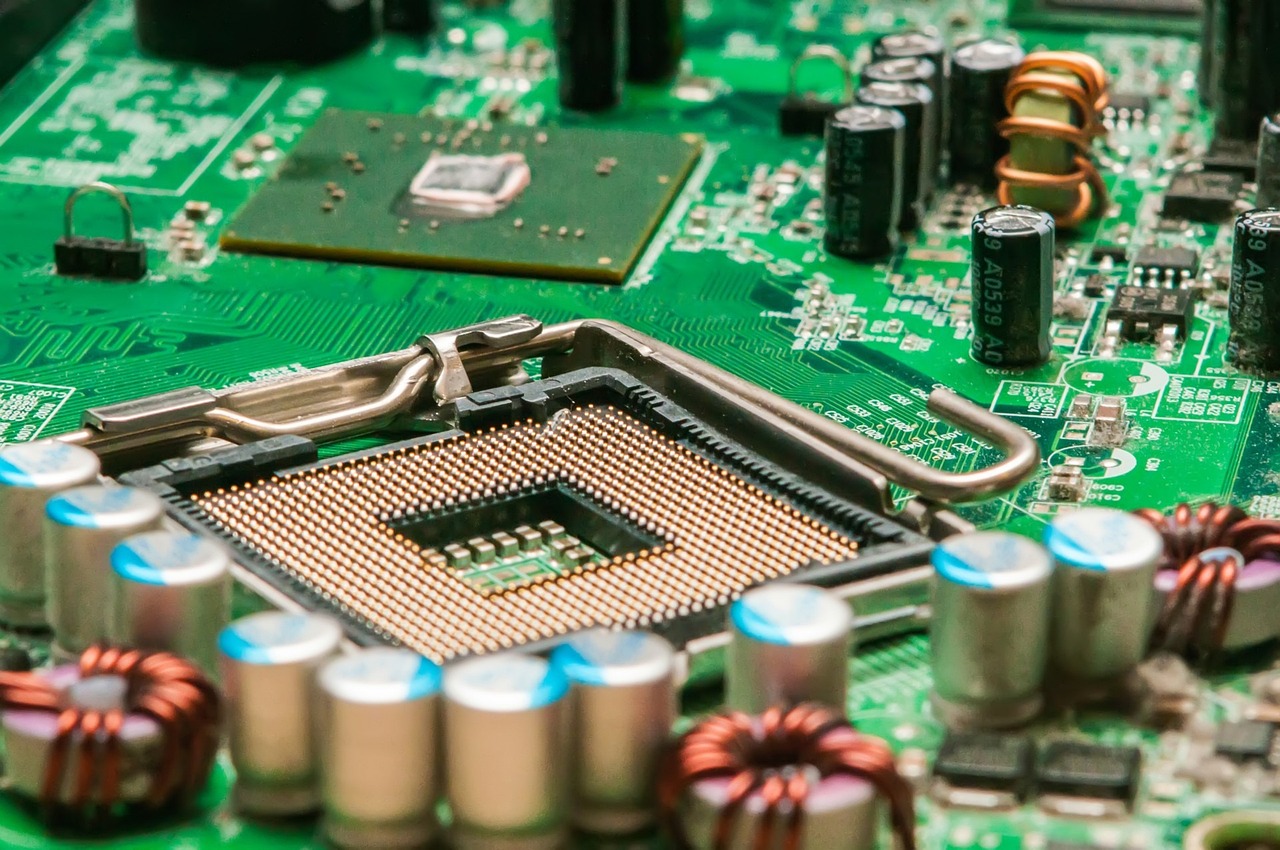

Electrolomas specialises in the manufacture of all types of electronic circuits, among other products and…

Digital transformation will help in the electronics sector

The contemporary technological revolution, marked by an unprecedented acceleration in innovation and technology, is reshaping the industrial landscape at a dizzying pace. Organizations face the constant challenge of adapting to the new complexities and dynamics of a continually evolving market. This article explores how digital innovation is transforming the product design and manufacturing sector, focusing on digital integration and continuity as fundamental pillars for business success.

Digital Transformation: an imperative in design and manufacturing

The new reality of organizations

Companies engaged in product design and manufacturing are undergoing significant changes due to the demands of an ever-evolving product environment. Adaptation is not optional; It is a strategic necessity to stay competitive. Digital innovation, in this context, plays a crucial role by directly affecting all industrial sectors.

Pillars of digital innovation

Digital integration

Digital integration is essential to optimize practices, tools and application environments. It allows data and workflows to be combined and exchanged efficiently, facilitating a more holistic and synchronized approach to the product development process.

Digital continuity

Digital continuity provides continuous access and visibility over relevant data and information. This aspect improves collaboration between teams and optimizes decision making, key elements to streamline processes and increase operational efficiency.

Advantages of integrated digital processes

- Rapid implementation of changes: The ability to quickly adapt to market needs is crucial. Digital integration facilitates this flexibility.

- Centralized design libraries: Simplified access to essential resources, reducing search times and increasing productivity.

- ECAD-MCAD Collaboration: The interaction between electrical design (ECAD) and mechanical design (MCAD) becomes more fluid, which is critical for the integration of complex systems.

- Workflow management: Well-structured and digital processes allow for more efficient management and reduce the margin of error.

- Continuous feedback: The ability to request and review feedback at each stage of the design helps improve the quality of the final product.

Electrolomas: your partner in innovation

At ELECTROLOMAS, we understand the importance of keeping up to date with these technological innovations. We offer comprehensive services that range from the manufacturing of printed circuit boards (PCB) to their assembly, ensuring that your company can effectively respond to the demands of quality, speed and flexibility.

Conclusion

Digital transformation in product design and manufacturing is not just a trend, but an essential strategy to survive and thrive in a competitive market. Companies that embrace effective digital integration and continuity will be better positioned to lead in the era of constant innovation. Discover how ELECTROLOMAS can be your ally on this journey towards digital excellence.

This approach not only ensures relevance in a changing market, but also prepares organizations for future challenges, positioning them as leaders at the technological forefront.