Through circuit industrialization, a successful prototype is transformed into a product ready for mass production…

Characteristics and advantages of THT circuits

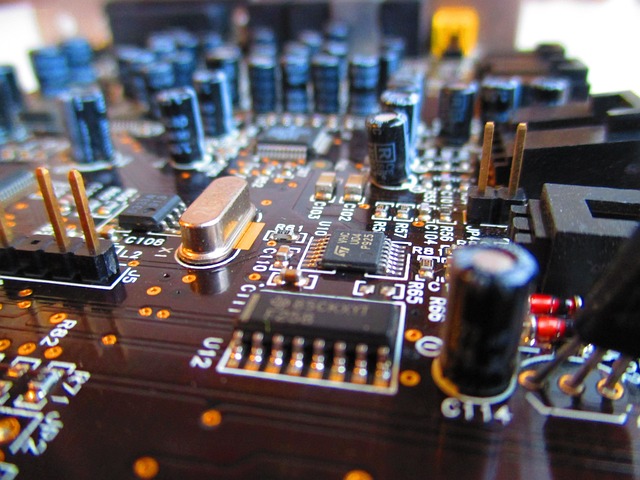

At present, there are various techniques for assembling components on a printed circuit board (PCB). One of them is based on THT (Through-Hole Technology), which has been used for decades. But what exactly are THT circuits? What advantages do they offer in a constantly evolving electronics industry? At Electro Lomas, as specialists in the assembly of these systems, we will clarify these and other issues.

What are THT circuits?

THT circuits are those that incorporate electronic elements into the PCB through pre-drilled holes. Thus, these components are soldered into place at the bottom of the PCB, creating a solid and reliable electrical connection.

This through-hole technology is more common in older electronic circuitry. However, although it is now used less compared to SMT (Surface Mount Technology) applied in the creation of so-called surface-mount devices (SMD or Surface-Mount Device), it is still a viable option for specific applications. In fact, it is especially useful when higher mechanical tolerance, higher current capacity, and greater ease of repair are required.

Although THT components can occupy more space on the PCB than SMT, they are widely used in applications that require high reliability (aeronautics, laboratories, automotive sector, consumer electronics, etc.). In addition, its technology makes it easier to hand-weld prototypes or small production runs, making it a widespread option for manufacturers of custom products.

Advantages of THT components

Broadly speaking, the main benefits of using through-hole technology are:

- High reliability. They offer a solid and reliable electrical connection, perfect for assemblies that require resistance and durability. Because they are connected to the PCB below, they are protected from impact and mechanical stress that can damage components soldered to the PCB surface.

- Higher current capacity. They allow to handle higher currents than SMT components. This makes them ideal for high power applications that require significant current flow, such as the automotive or aerospace industries.

- Ease of repair. Repair difficulty is minimal as components are easily removed and replaced. Thus, technicians can easily identify and replace faulty ones, reducing repair time and costs.

- Better thermal performance. They have a larger solder surface area than SMT components, which provides better heat transfer. In this way, overheating is prevented and the thermal performance of the PCB is increased.

- Suitable for specific applications. Although SMT technology is more popular today, THT circuits still have their place in specific applications. For example, for manufacturing small quantities of PCBs, prototyping, and custom production. They are also suitable for cases where a high mechanical tolerance is required.

In conclusion, THT circuits offer multiple possibilities and benefits for certain applications in different sectors. At Electrolomas, we are experts in assembling this type of through-hole technology with wave soldering and selective soldering. Contact us!