Choosing the best electronic component is a crucial step in developing a functional, safe, and…

What are the differences between electronic and electromechanical assembly?

Electronic assembly and electromechanical assembly should not be confused. Both refer to different processes, although they are still related. To take advantage of the potential of each one, it is advisable to understand them in detail. We will delve into this in the next few lines.

What is electronic assembly

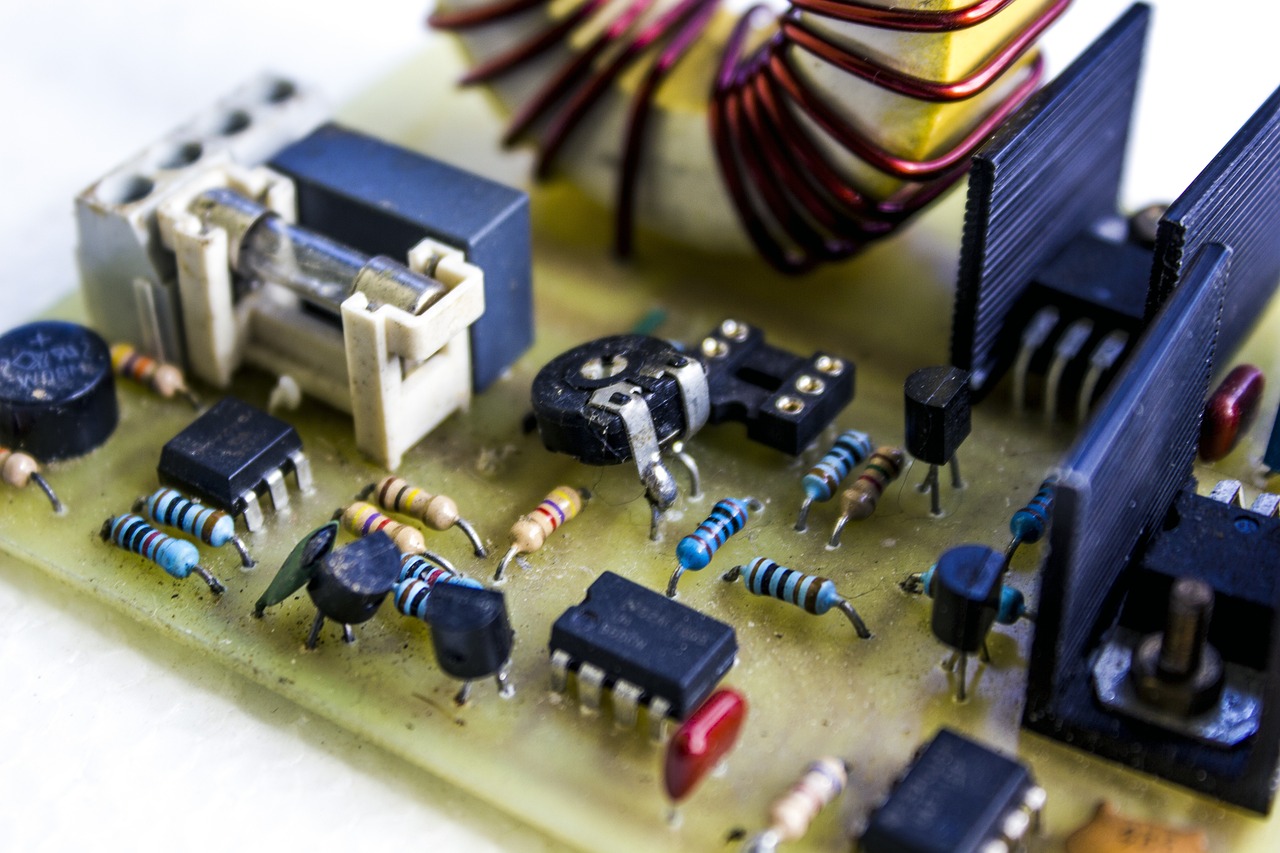

It is a meticulous process that involves placing and soldering electronic components on printed circuit boards. These can be as tiny as grains of sand or as big as books. Each one performs a specific function within a larger machine.

Accuracy is decisive during the assembly process, since a millimeter error is enough for the final product to be defective. To avoid such a problem, technicians use advanced tools like microscopes and precision tweezers. Likewise, they can resort to specialized welding techniques.

Electronic assembly often involves the use of automated placement machines that can install hundreds of components per minute. This process is essential in the manufacture of a wide range of electronic devices, from radios to satellite navigation systems. It also favors mass production, with the consequent reduction in costs that it entails.

It is a process that is present in the manufacture of a wide variety of electronic devices: from a mobile phone to a GPS.

And what is an electromechanical assembly?

Regarding electromechanical assembly, it is a crucial process in the creation of devices that claim to interact with their environment in a physical way. Their scale is larger, since they usually require the inclusion of motors, gears or actuators. This means that assembly is undertaken by hand or with the help of specialized machines.

However, precision continues to play a determining role. Thanks to it, it is guaranteed that the final product is robust and has a long useful life. It is a procedure carried out in the energy industry, for example, when installing pipes, electrical equipment or control systems.

It is an imperative assembly method for the manufacturing industry, for example. In this, it is a priority to guarantee the reliability and efficiency of the electromechanical systems, given that they are vital for operational success.

What is the difference between them

The main difference between both types of assembly lies in their approach and application. Electronic focuses on creating circuits through the precise placement of its components. As for the electromechanical, its purpose is to integrate each element into larger mechanical systems that interact with each other.

Furthermore, an electronic type assembly is usually very automated, something that does not happen with the electromechanical one. This still has a high manual intervention to assemble specific parts, such as an engine or gears.

In short, electronic and electromechanical assembly can be conceived as two sides of the same coin. Although they act at different times, they are unavoidable in the manufacture of basic devices for modern life. At Electromas we have a wide variety of components for both processes. Just consult our catalogs to know them in depth.