SMD assembly with AOI has been growing in importance in recent months. It is an…

What are AOI optical review systems during electronic production?

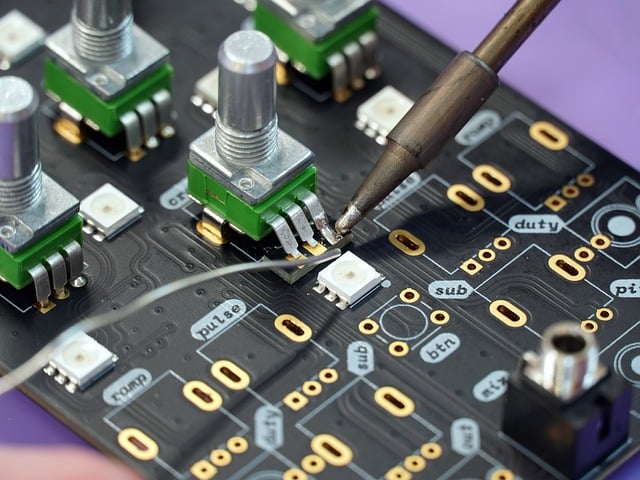

When undertaking work related to the production of electronic elements, AOI optical inspection systems are used to increase reliability and quality. We will discuss what they consist of and why they are key to differentiating yourself from the competition.

What is an AOI review machine?

The acronym refers to automated optical inspection. The process consists of the device visually and automatically reviewing a printed circuit, a transistor, an LCD or the labels of a product. Each machine is connected to a program that has a sample image. If the captured and saved data do not match, a warning about the anomaly is generated.

Thus, it seems logical to deduce that the use of this machinery in electronic production is essential. Only in this way is it possible to know whether all the circuits, parts or products, in general, comply with the established parameters or not.

What are the advantages of using AOI review?

At Electrolomas there is an AOI review machine, which allows the supply chain to be significantly improved. Industry 4.0 has managed to revolutionize production systems. The final objective is to analyze the data generated by the manufacturing of a product and measure it in real time. The greater the precision when reviewing a circuit, the more competitive the company will be.

Since the machinery was acquired, it has been noticed that it is easier to detect defects, which makes it possible to save on manufacturing materials. At the same time, performance has increased by detecting defects in time, allowing production to be stopped immediately. This means that data flows, throughout the supply chain, in all directions. You gain in responsiveness and quality. In fact, AOI technology makes it easy to detect:

- The presence of components that do not match those of the programmed image.

- The absence of essential parts. As soon as the first one passes the sensor, an alert is sent and production can be stopped.

- An incorrect placement of the components.

- Stains, scratches or nodules on the electronic board.

Checking a part saves 20 seconds and the operator does not have to intervene, unless an error is detected. It seems easy to deduce that competitiveness is guaranteed.

What will be the future of AOI technology in electronic production?

It is expected to be widely implemented in all industrial sectors. Modifying the parameters of the program that manages each AOI system is so simple that it encourages confidence in its undoubted effectiveness. Not in vain, it is possible to stop the production of an article in seconds, reprogram the machinery and continue with manufacturing, without this posing an economic problem for the company.

On our social networks you will always find current topics, such as this one related to AOI optical review systems. Do not hesitate to review our commercial offer and do not hesitate to request our professional advice. We are here to improve the productivity of your business machinery. Trust our experience and start a new stage.