Innovations in medical electronics are advancing rapidly. Significant technological initiatives and achievements are emerging, such…

EVO Cam inspection equipment and electronic circuit creation

Digital microscopes are characterized by incorporating a digital camera instead of an optical one. In this way, the captured image is projected in real time on a monitor. In this sense, the EVO Cam inspection is highly resolute, powerful and highly versatile. Therefore, its applications are numerous in various industries and sectors.

What are EVO Cam inspection equipment? Uses and functions

A digital microscope consists of different optical devices and a digital camera connected to a computer monitor. In the case of EVO Cam inspection equipment, they have different configurations depending on the version purchased. However, they are characterized by their high image quality and the possibility of achieving an optical magnification of up to 725x. However, thanks to their digital zoom, this can be increased.

Most digital microscopes require software for advanced tasks. They offer different features, such as recording videos, improving images, editing, etc. In EVO Cam microscopes, there are four options for this type of program depending on the needs of each client.

The possibilities are diverse and of different natures. Thus, they find application in the automotive industry, in order to check various elements, such as brakes, art restoration or to detect counterfeit bills or documents. It is also very useful when manufacturing electronic circuits and, in general, in all those tasks that require great precision, such as in medicine.

What do these elements contribute to manufacturing circuits?

These systems, together with their software, allow for the precise measurement of tiny and complex parts quickly. To do this, they use point-to-point measurements or superpositions for image comparison. These calibrations or results are saved in the form of presets or established adjustments. In fact, they can be tracked using the zoom to speed up the measurement. Thus, recalibration will no longer be necessary.

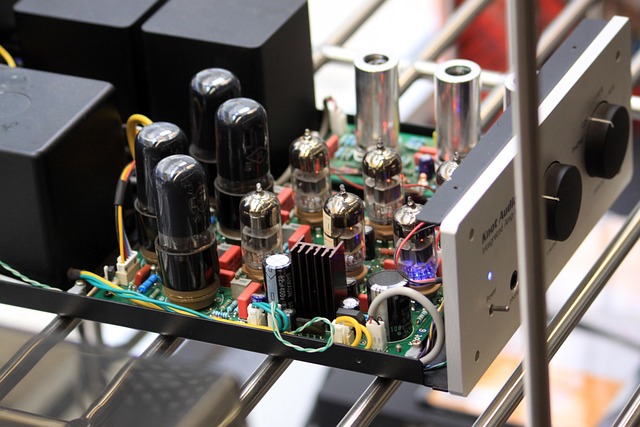

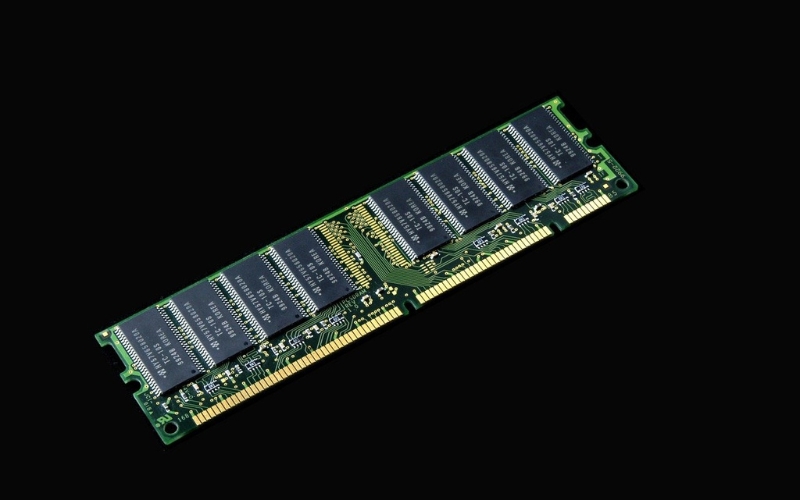

Digital microscopes are essential in the electronics industry. With them, any technician has the possibility of analyzing printed circuit boards and verifying their integrity. However, they go further, since with them these circuits can also be manufactured from scratch. With these, the professional will not need as many rest periods as with analog microscopes.

In addition, the EVO Cam series is so intuitive that it is not even necessary to invest time and money in training operators. Anyone, even with little knowledge, can work with these devices. On the other hand, the menu is multilingual, which also eliminates the language barrier in its technology.

The EVO Cam inspection came to revolutionize the manufacture of electronic circuits, gaining in efficiency, precision and time. These digital microscopes minimize the possibility of making an error and their usability is more intuitive than that of analog ones. At Electrolomas, we are specialized in their use and have extensive experience in circuit manufacturing. Therefore, if you need personalized and non-binding advice, the best thing to do is to contact us directly.