When developing modern medical devices, mixed cabling design is an absolutely critical challenge. These devices…

What requirements must a printed circuit board or EMS assembly for medical devices meet?

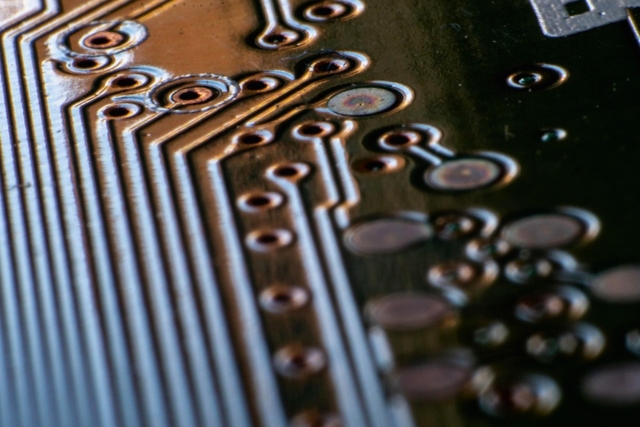

Electronic circuits for medical devices with EMS assembly demand high standards of quality, safety, and reliability. This post from Electrolomas explains which standards, processes, and controls a manufacturer must comply with to ensure they are safe and compliant.

Essential Standards and Certifications in Medical PCB Manufacturing

When manufacturing circuits for medical devices, different standards and certifications apply to guarantee quality, reliability, and patient safety:

- ISO 13485. This is the highest standard for quality. It requires controlled processes, complete traceability of materials, proper risk management, and continuous validation of design and production. It requires documenting all stages, ensuring consistency between batches, and maintaining records.

- IEC 60601. This standard focuses on the electrical and electromagnetic safety of medical equipment. In fact, it influences PCB design and regulates the performance of electromagnetic compatibility and robustness testing against interference. Among other aspects, it validates insulation, track spacing, leakage control, EMC shielding, and the selection of materials that minimize electrical risks.

- ISO 14971 and IPC-6012/IPC A-610 complete the regulatory framework because they uphold acceptability criteria, structural reliability, and manufacturing tolerances. ISO 14971, specifically, addresses risk management.

Importance of these standards

This regulatory compliance means integrating safety from the design stage. Thus, thanks to these standards, printed circuit boards and PCBs are manufactured to be safe, stable, and fully traceable.

Essentially, failures are reduced, and compliance with the standards required for clinical use is ensured. The selection of biocompatible materials, thermal control, redundancies, verification, and rigorous validation are its fundamental aspects.

Controls, Tests, and Best Practices in EMS Assembly of Medical Devices

During the EMS assembly of medical devices, strict controls and best practices are applied to ensure the reliability and safety of the results.

In the design phase, only certified components and biocompatible materials are selected, always in accordance with applicable electrical and thermal requirements.

Furthermore, each stage incorporates AOI (Automated Optical Inspection), which consists of a series of functional tests and electrical verifications to detect early defects.

Of course, complete traceability of components and batches is rigorously documented to ensure historical control and the assignment of responsibilities.

Finally, final validations are carried out to verify performance and safety according to medical regulations.

In this way, it is guaranteed that the installed medical devices are safe, reliable, and meet the regulatory and quality standards required in clinical environments. At Electrolomas, all these excellent manufacturing criteria are applied during printed circuit board production and EMS assembly. Here is their contact information!