SMD assembly with AOI has been growing in importance in recent months. It is an…

Three differential machines in the production of electrical circuits

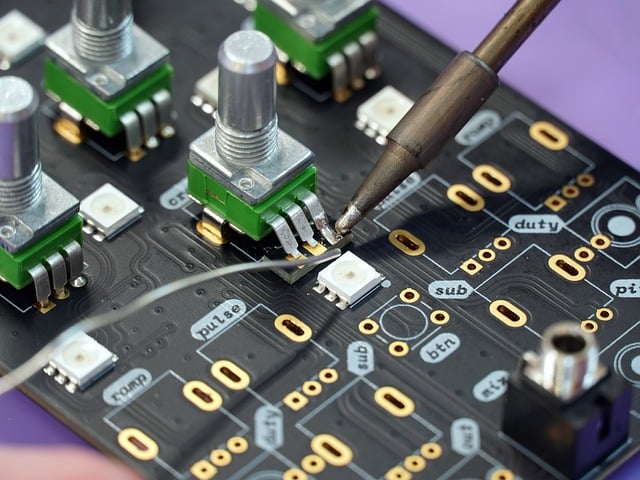

The production of electrical circuits is a delicate task that requires precision and quality from professionals. When choosing a supplier, it is essential to consider the machines used in the process. This article delves into three machines that distinguish the production of the best electrical circuits. All of them form an integral part of the advanced Electrolomas production park.

What machines distinguish the most reliable production of electrical circuits?

Behind the creation of quality electrical circuits, three electronic machines are hidden that not only define the effectiveness, but also ensure the reliability of each component produced. We must not forget that machinery stands as one of the fundamental pillars behind the best electrical products.

1. High precision CNC milling machine

This sophisticated equipment, controlled by a computerized numerical system, redefines precision standards in the manufacturing of electrical components. At the core of its functionality is CNC technology, which allows programming the execution of cuts and engravings with microscopic precision.

The ability to translate complex digital designs into exact physical actions ensures faithful reproduction of conductive traces and components, ensuring consistency across every PCB produced.

Another distinctive feature is its versatility in routing a wide variety of materials, from conventional to more advanced and sensitive ones.

2. Automated screen printing printer

The main feature of this printer lies in its ability to automate the screen printing process. This automation not only significantly increases production efficiency, but eliminates the variability associated with the human hand. Thus, it undertakes a uniform application of inks on each PCB. Its precision is essential to achieve sharp traces and components.

This machine stands out for its ability to apply a wide range of inks and materials, including the conductors and insulators required for the creation of electrical circuits. This versatility enables it to adapt to design requirements, offering a customized solution for each application, without compromising quality.

3. Automated Optical Inspection (AOI) Machine

AOI stands as the last line of defense in the production of high-quality electrical circuits. It brings an incisive and meticulous look to each component. The heart of this machine lies in its high-resolution cameras, capable of examining any detail of a printed circuit board (PCB).

This capability favors early detection of potential defects, from short circuits to faulty welds. Thus, it guarantees that each component meets the most demanding quality standards.

When choosing an electrical circuit supplier, attention to the machines used in the production process is essential. The high-precision CNC milling machine, automated screen printing printer and automated optical inspection machine are decisive components that distinguish Electrolomas in the production of reliable electrical circuits. These advanced technologies guarantee precision, uniformity and quality in every step of the production process, providing top-notch electronic products. Call us for more information!