Electronic circuits for medical devices with EMS assembly demand high standards of quality, safety, and…

Complete Printed Circuit Board Manufacturing Process: From Design to Assembly for Medical Devices

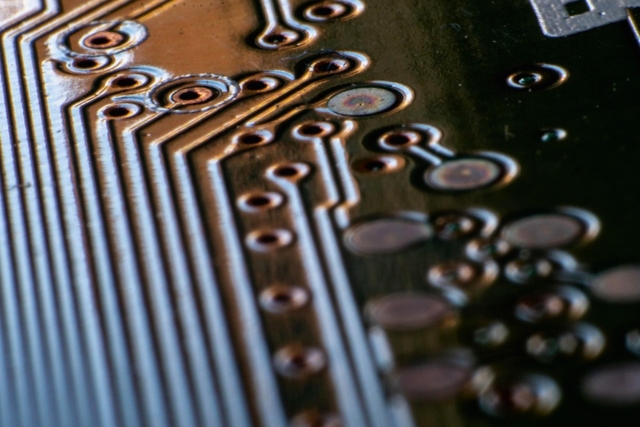

The manufacture of highly reliable, traceable, and safe printed circuit boards has become vital for the most advanced medical electronic equipment. Even the smallest technical failure compromises the operation of the device’s electronic circuit and, consequently, patient safety.

In practice, the manufacture of flexible PCBs and the assembly of medical equipment must follow perfectly defined phases and ensure compliance with demanding technical and regulatory requirements. This Electrolomas article explains it all.

The manufacture of highly reliable, traceable, and safe printed circuit boards has become vital for the most advanced medical electronic equipment. Any small technical failure compromises the operation of the device’s electronic circuit and, consequently, patient safety.

In practice, the manufacture of flexible PCBs and the assembly of medical devices must follow perfectly defined phases and ensure compliance with demanding technical and regulatory requirements. We explain this in this Electrolomas content.

Key stages in the manufacture of printed circuit boards for medical devices

When seeking maximum reliability, validation, traceability, and regulatory compliance in medical electronics, it is essential to fulfill the various key phases when manufacturing these printed circuit boards:

- Schematic and layout design. The electronic circuit is defined according to the device’s requirements and uses, the certified components that make it up are selected, and the PCB is designed considering signal integrity, isolation, and heat dissipation. Finally, the design rules (DFM and DFT) are applied.

- Prototyping. The first units are manufactured for validation. Functional or design errors are detected as early as possible, and everything is adjusted before moving to mass production.

- PCB Manufacturing. Using the appropriate materials, etching, drilling, and metallizing processes begin. Dimensional and layer control are applied, and tolerances and process repeatability are validated.

- Electrical Testing. This begins with the corresponding continuity and insulation tests. Short circuits and open circuits are then detected, and finally, compliance with electrical specifications is verified.

This stage is therefore fundamental to reducing subsequent failures and ensuring the stability of the medical device.

Assembly and Quality Control for Medical Use

In this phase, the electronic components are mounted on the board using automated or high-precision manual processes.

The following assembly and mounting practices for medical equipment are recommended:

- Component Mounting. SMT and THT technologies are applied according to the design, soldering is performed using reflow or controlled wave soldering, and handling takes place in environments protected against electrostatic discharge.

- Visual inspection and control. This includes automated optical inspection (AOI), manual inspection of the most critical components, and detection of soldering or positioning defects.

- Functional testing. Once the actual operation of the circuit is verified, the operating conditions of the medical equipment are simulated to identify intermittent or thermal failures.

- Quality control and traceability. This begins with the registration of batches, components, and processes; continues with complete assembly documentation; and ends with confirmation of compliance with all regulations and medical standards.

The benefits of this meticulous control are greater long-term reliability, reduced operational risks, and increased trust in the manufacturer. At Electrolomas, these procedures are carried out with professionalism, sound judgment, and experience. When printed circuit boards for the medical field require absolute precision, they are the best choice. Contacting them is synonymous with reliability and complete peace of mind.