For those who are not experts in electricity, there is often a very common confusion:…

How Electrolomas approaches industrialization step by step

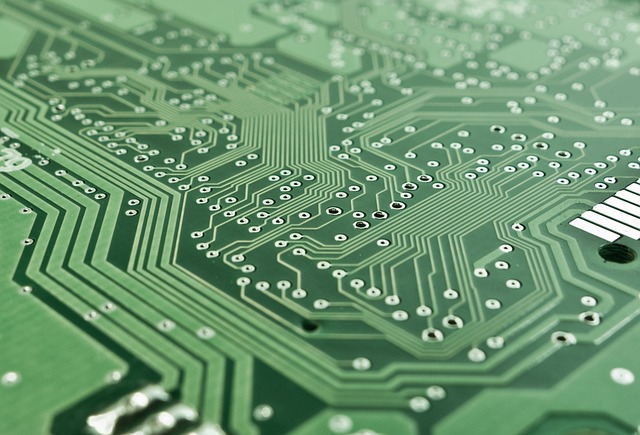

Through circuit industrialization, a successful prototype is transformed into a product ready for mass production. This process includes ensuring that quality standards, technical regulations, and economic viability are met. In the world of electronics, only precision, experience, and planning make it possible to evolve a functional design into stable and repeatable manufacturing.

Success is only achieved by leveraging the expertise of specialized partners who support the customer throughout the entire process. From design validation to mass production, each phase is decisive. Electrolomas offers a comprehensive, certified approach that avoids risks and guarantees the expected results.

Key steps in circuit industrialization

In reality, industrializing circuits is much more than replicating a prototype. It refers to a technical and regulatory process that improves the prototype until it can be manufactured with the desired efficiency, consistency, and quality.

To do it well, it is important to follow the usual steps of this procedure:

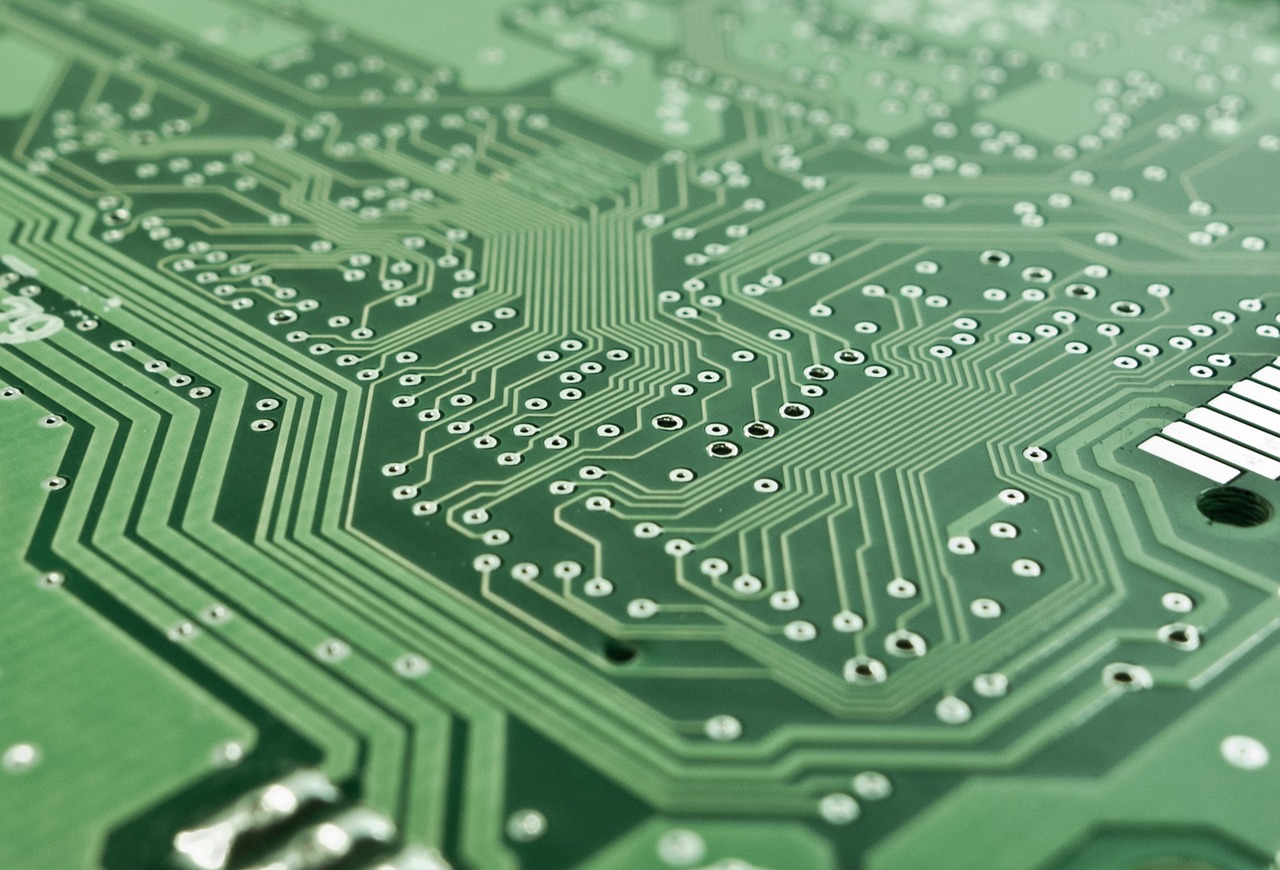

- Validate the design. This involves reviewing the schematics, PCB layouts, and ensuring compatibility with the various applicable regulations. Primarily, CE, RoHS, and UL. What is it for? To detect improvements, reduce costs, and ensure that the final product will be reliable.

- Optimize the design for manufacturing (DfM). This is the time to consider the machinery and assembly processes (SMT, THT). In parallel, it is necessary to ensure that the components will be guaranteed and that testing will be possible and easy. Applying the technical instructions for each stage entails carrying out other urgent tasks, such as defining the final bill of materials (BOM) and promoting the production layout.

- Create the pre-production prototype. This is the last real test before scaling up, as this zero production allows for identifying possible deviations and fine-tuning assembly, testing, and packaging processes.

- Produce in series. This must always be done with systematic quality control. It often includes functional testing, automatic optical inspection (AOI), X-ray inspections, and full traceability.

- Obtain approvals. All products must pass the Corresponding approvals. There are highly regulated sectors where this aspect is more comprehensive and demanding. This is the case in the automotive, healthcare, and telecommunications industries.

How Electrolomas approaches industrialization step by step

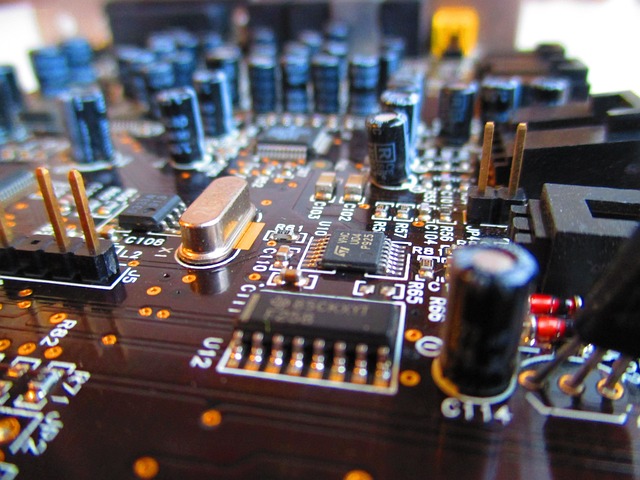

Electrolomas is the comprehensive solution when moving from design to market. Relying on the support of a specialized technician is the best option. Its staff thoroughly reviews electronic prototypes, detects areas for improvement, and adapts the design to each and every one of the requirements of industrial manufacturing.

It is no coincidence that this company is ISO 9001 certified. From the very beginning of the collaboration, it ensures the highest quality processes in all its plants. It also has access to automated SMT and THT lines, testing laboratories, and customized test benches to ensure that each circuit meets customer requirements.

It also provides advice on technical documentation to comply with regulations and facilitates the testing necessary to obtain approvals. In other words, its work is not limited to production; Because it also provides excellent solutions in logistics, packaging, and post-production support.

Circuit industrialization is the bridge between innovation and the market. To achieve efficient and error-free mass production, a good design is not enough: experience in processes, regulations, and quality is essential. Electrolomas is the best demonstration of how a specialized company can successfully transform electronic prototypes into industrial products, applying top-level technology, methodology, and certifications. Choosing the right partner makes the difference between a successful development and a failed project. To get off to a good start, we recommend contacting us.