Heat-shrink termination of a cable is one of the most effective solutions available for insulating…

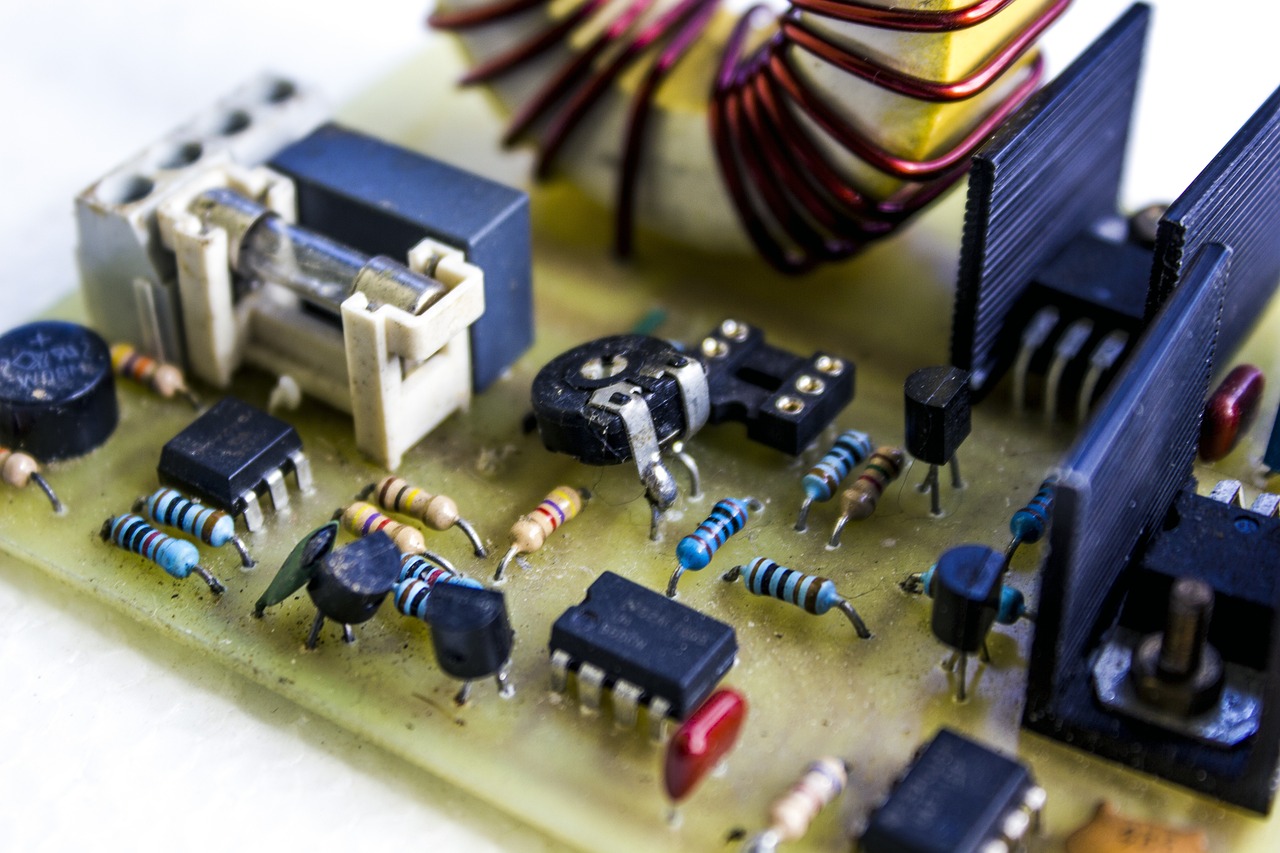

How to choose the best electronic component for your prototype?

Choosing the best electronic component is a crucial step in developing a functional, safe, and scalable prototype. Throughout the entire process, from the initial design stage to final integration, a poor choice leads to performance failures, cost overruns, or delays.

Therefore, the most relevant differences in these situations are these two: having good technical guidance and turning to expert partners, such as Electrolomas.

This article analyzes what to consider when selecting components correctly. And then, how this leading technical partner is a great help in prototyping.

Technical and regulatory criteria for component selection

These are the steps indicated when choosing the best electronic component:

- Clearly define the technical requirements of the prototype: voltage, current, thermal tolerance, frequency, and electromagnetic compatibility.

- Take into account the environment where the product will operate. This is not the same as whether it will be exposed to humidity, dust, or vibrations, for example.

- Establish the mounting format. There are two main options: SMT (Surface-Mount Technology) and THT (Through-Hole Technology).

- The former is best for compact, automatable devices with a high component density. The latter is for test prototypes or when greater mechanical strength is required.

- Verify that the components have passed the most recognized certifications. Back-up labels such as CE, RoHS, or UL are essential for marketing these products. They guarantee compliance with applicable international safety and sustainability regulations.

- Ensure scalability. Some brands guarantee component availability and access to technical documentation. Others do not. Having the former means fewer subsequent replacement or redesign issues.

How Electrolomas supports the prototyping phase and guarantees the best electronic component

When customers feel fully supported by their supplier throughout the entire prototype development process, satisfaction is enormous. Electrolomas provides ongoing support to each customer. This begins with component selection and continues through final validation. Being supported in every decision by the electronics engineers in its technical office means improving the design, requirements, and available budget. This makes achieving the optimal solution much more feasible.

These are the services and support that Electrolomas provides to its customers:

- Technical review of the electrical schematic and review of the bill of materials (BOM).

- Suggest equivalent components that offer better availability or are more economically priced.

- Collaborate in regulatory and certification verification processes.

- Market a large stock of components from numerous international suppliers.

- Support and assist in the compatibility and assembly processes.

The support of this ongoing personalized assistance helps minimize, or even eliminate, the risk of incompatibilities. In addition, it’s easier to avoid oversizing and bottlenecks when purchasing materials. And all this is achieved by better cost control: the process is cheaper without sacrificing quality or performance.

Therefore, when creating a prototype, choosing the best electronic component is a fundamental issue. It’s not just about finding a suitable nominal value, but also about understanding the entire system, its future needs, and the regulations that govern it.

Leveraging Electrolomas experience and know-how allows for confident and efficient decisions, as it speeds up the process from idea to product. Its technical approach and close relationship with manufacturers make its services far more than advantageous.

In short, to achieve solid and sustainable development, selecting the best electronic component is a strategic factor from the outset. For personalized advice, simply contact us.