Both flexible circuits (FPCs) and rigid circuits are fundamental in modern industrial electronics. It's important…

Trends and Innovations in Medical Electronics

Innovations in medical electronics are advancing rapidly. Significant technological initiatives and achievements are emerging, such as miniaturization, flexible boards, and complex flexible wiring and assembly solutions.

This content explains current trends, key technical innovations, and Electrolomas‘ role in this reality.

Evolution of Medical Electronics: From Rigid Boards to Flexible and Compact Solutions

Medical electronics has undergone an extraordinary transformation, the main manifestation of which is the shift from bulky systems with rigid printed circuit boards (PCBs) to flexible and compact solutions.

Miniaturization and Design

The determining factors in this evolution are miniaturization and high-density assembly. Thanks to current advances in manufacturing and design, it is possible to integrate more components in much smaller spaces.

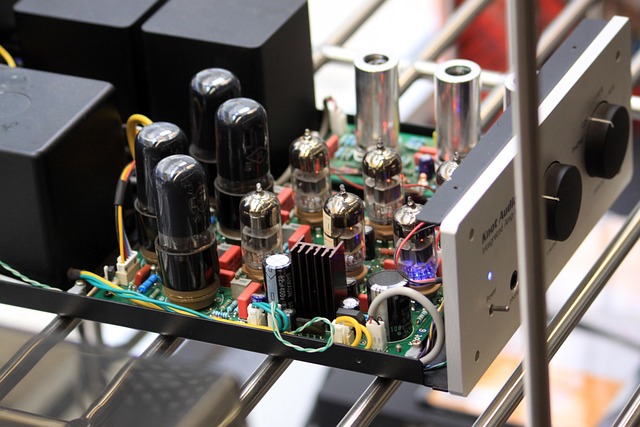

Previously, boards were rigid, large, and heavy, severely limiting portability. Now, flexible PCBs (FPCBs) are adapting to the anatomy and limited space of wearable devices. Patient monitors and implantable devices are good examples.

Materials and manufacturing.

The change in materials is also striking. Rigid PCBs used to employ FR-4; that is, fiberglass and epoxy resin. Now, FPCBs incorporate polyimide or polyester, materials that offer flexibility, strength, and biocompatibility.

Possibilities and innovations in medical electronics.

Devices are much smaller, more portable, and more efficient, enabling more accessible and less invasive healthcare. Wearable monitoring devices have improved patient comfort, as is the case with ECG patches and wearable sensors. In addition, advanced implants have decreased in size: pacemakers and neurostimulators are becoming increasingly smaller.

New Opportunities Thanks to Innovations in Medical Electronics

Connectivity and integration are the new major focuses driving the evolution of medical devices:

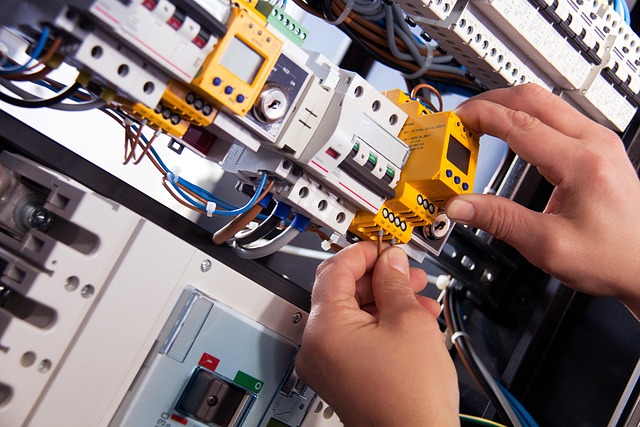

- Custom, flexible cabling optimizes adaptability and improves the performance of small, portable devices.

- Modular production enables the efficient assembly of subsystems, essential for scalability and, consequently, customization.

- Hybrid PCB assemblies combine rigid and flexible PCBs in a process called rigid-flex.

The future looks promising and strategic, based on the standard that combines techniques and integrates electromechanical systems. Electrolomas is leading these innovations in medical electronics, from design to manufacturing, accelerating the launch of smarter and far less invasive healthcare devices. It’s time to contact this company!