What is THT assembly and what is selective welding? These are the two main questions…

Reflow soldering, what is it?

Reflow soldering, also called reflow soldering, is a very effective method for assembling printed circuits and soldering electronic components, obtaining precise and efficient results. Based on this useful information, this article from Electrolomas describes what this type of soldering is used for and what advantages it provides. In addition, several reasons are provided for choosing Electrolomas as a specialized company.

What is reflow soldering used for?

Reflow soldering is characterized by melting and firmly fixing each component in its place. Therefore, when using it, solid and long-lasting connections are achieved and, therefore, the circuits work without interruptions.

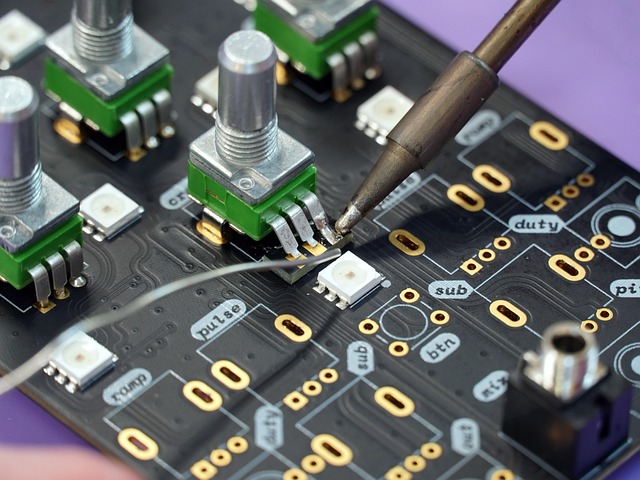

Reflow machines use the specific method of heating a paste to solder components and join them to the electronic boards. This paste is used in a controlled manner so that it melts and, in this way, the components can adhere without damaging the sensitive elements. Likewise, this advanced process helps improve assembly precision. It is very useful for devices that perform work in harsh environments or that need to operate for a long period of time without interruptions.

Due to its characteristics and performance, this solder is used in many sectors to manufacture complex electronic products with maximum accuracy.

Advantages of reflow soldering

Reflow soldering stands out for having optimal temperature control from the heat applied at specific levels. In this way, each step contributes to ensuring that the components act correctly and withstand wear, especially in applications that must operate with constant performance.

Another benefit to be valued from reflow soldering is its high mechanical resistance, which provides the strength in the fusion of parts. In other words, this technique enables the joints to better withstand physical stress, resulting in stable connections, even under demanding conditions.

It should not be overlooked that this process allows working with different components and complex circuit boards, which results in optimized performance.

Reflow soldering at Electrolomas

Not all companies offer the same results. For example, Electrolomas, an expert company and benchmark in the national sector, uses advanced reflow machines. For this reason, it stands out for executing precise and long-lasting welds. In addition, these systems adapt perfectly to the specifications of each professional sector.

This company has a technical team, made up of personnel with many years of experience, which enables it to guarantee that each of its reflow welds meets all safety and quality standards. These standards are usually those required in such demanding sectors as access systems.

In addition, each process is undertaken with equipment that carries out exact control of the heat and reflow time. In this way, safe and resistant electrical joints are achieved. Thanks to its advanced technology, uniform solders are created that present the best consistency and reliability at each connection point. This is crucial, for example, in electronic equipment that is exposed to constant vibration or humidity conditions.

In short, reflow soldering is essential to safeguard the functionality of circuits in advanced applications. At Electrolomas they provide high quality services. For more information or to receive personalized advice, it is recommended to contact them directly.