Innovations in medical electronics are advancing rapidly. Significant technological initiatives and achievements are emerging, such…

Main challenges in electronics for 2025

To maintain its technological leadership, Electrolomas always seeks to anticipate the new challenges of modern electronics. For this reason, it shares its expertise in this article, leveraging its know-how to outline the major trends in the electronics sector for 2025.

What Are the New Challenges in Electronics?

Keeping up with the latest developments in electronics is essential for providing top-tier service to customers. This allows Electrolomas to lead innovation in electrical circuits and electronic systems in general. But what are the key advancements for 2025?

1. Extreme Miniaturization in the Electronics Industry

A widespread trend across almost all technological solutions is the preference for increasingly compact and powerful devices—in other words, those with a smaller size.

To achieve this, designs and manufacturing processes are evolving, particularly as new innovations from wearable technology, the Internet of Things (IoT), and medical electronics are being applied.

Today, engineers are working on developing creative and innovative solutions to address this challenge. Everything indicates that by 2025, highly complex electronic functionalities will be integrated into much smaller formats.

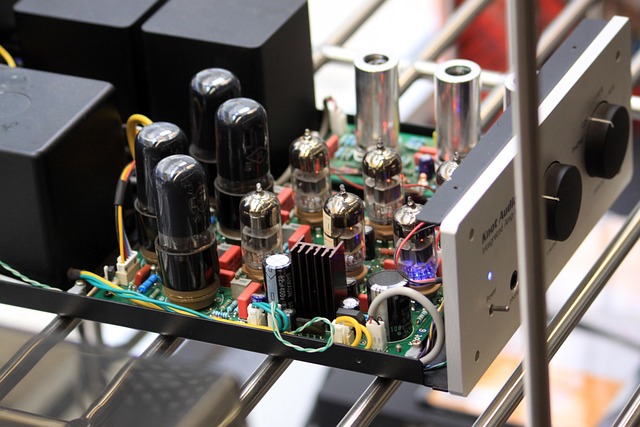

2. Smart SMD Components: The Future of Technology

Continuing with the trend of size reduction, smart SMD components are paving a clear path for technological evolution, as they enable autonomous data processing. Their small size, efficiency, and versatility position them as a revolutionary source of solutions.

3. Green and Sustainable Electronics

Environmental awareness is driving another line of innovation in modern electrical circuits. There is a strong focus on producing electronics in a way that is more environmentally friendly.

This technological push is present in all phases of the process. To reduce environmental impact, more sustainable and eco-friendly designs are being tested. Additionally, improving electronic waste management, maximizing the use of recyclable materials, and reusing electronic components more extensively are all crucial aspects of this initiative.

Of course, efforts are also being made to reduce energy consumption in electronics manufacturing processes without compromising quality. Finally, 2025 is expected to promote the circular economy.

4. Industry 4.0 Manufacturing

Companies that incorporate advanced digital technologies into their industrial electronics processes are achieving excellent results. Thanks to automation, IoT, and data analytics, they are optimizing production and improving efficiency in factories.

Another positive outcome of Industry 4.0 manufacturing is the creation of more flexible and adaptable work environments. Smart machinery and cyber-physical systems collaborate in real-time.

Among the many benefits of this production revolution, three key aspects stand out:

- More personalized products tailored to each customer’s expectations.

- Lower costs.

- Faster production times.

In an environment where the new challenges in electronics demand fast progress, choosing technologically advanced suppliers is crucial. Contacting Electrolomas is the best way to ensure a more comprehensive, satisfying, and innovative service!